delfim pedrosa

industrial electronics and computers eng.

industrial electronics and computers eng.

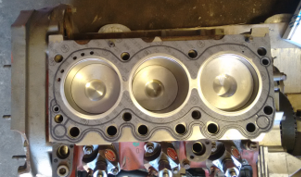

It was repaired the air-cooled inline three-cylinder Deutz diesel engine. The engine was repaired from A to Z, where it took the new timing belt, new head gasket, new crankshaft, new bushings, new pistons, rings and liners, new valves, new gasket set and new starter motor. The 3 independent injection pumps were stuck. It sent to the technician to be repaired, as well as the fuel injectors have been revised. At the end of the repair, the engine was coupled a 23 kVA three-phase generator.

It was repaired the air-cooled V8 Deutz diesel engine. The cylinders were polished, the valves were rotated, valve clearance adjustment and it was put new piston rings. It was done the overhaul with new filters and oil. At the end of the repair, the engine was coupled an 80 kVA three-phase generator.

The engine was repaired because it fell to the ground and broke some parts. The crankcase was rebuilt, as well as the oil suction pipe. The oil inlet, oil filter bowl and ventilation turbine holder were rebuilt and rectified. The engine had oil leaks through the push rod tubes, it was necessary to replace the rubber tubes that made the connection between the push rod tubes, the engine block and the heads. When removing the heads, it was observed that existed coal around the valves and on top of the pistons. The cylinders were removed to check the pistons rings. As it was an engine that was stopped for a long time and with possible water inlets for the pistons, due to the damaged air filter compartment, it was observed that some rings were stuck. The heads and pistons were cleaned using an ultrasonic bath. The cylinders were polished and the valves were cleaned and rotated. As it is difficult to find material for this type of engine, the gaskets were made of appropriate cardboard. The seals between the cylinder liner and the engine block were also new. The injection pump and injectors were revised. Exists very low information about the calibration of this type of injection pump and the lack of material to repair it. The needed material came from Turkey. After the parts went to the mechanical turner for adjusting to the pump. The calibration was made by a man who has worked with this type of injection pump 40 years ago because there is no calibration table for this type of pump.

It was repaired the three-cylinder International Harvester diesel engine. The engine was repaired from A to Z, where it took the new head gasket, the crankshaft was rectified, new main and big end bearings and new pistons, rings and cylinder liners. The cylinder head was rectified, the valves were rotated and clearance adjustment. The injection pump and fuel injectors were revised. A new piston rod and push rod were purchased. It was also purchased a new gasket set. The repair of this engine was due to the bolts of a piston rod broken and consequently drilling the engine block. The engine block has been repaired and rectified. The flywheel has been rectified and the clutch has been repaired.

It was repaired the air-cooled inline two-cylinder Lombardini LDA672 diesel engine. The engine needed to be repaired because the wrist pin came out and scratched the cylinder liner. When I received the engine, it was all disassembled because the previous owner did not want to repair it. The crankshaft had already been rectified several times, in main and rod bearing journals, being at the rectification limit. It was purchased a new crankshaft and main and big end bearings. It was also purchased a new injection pump because it was cheaper than repair the old. The fuel injectors were repaired with new nozzles. The starter motor and the crankshaft support, flywheel side, had to be new because the old ones were broken. The crankshaft pulley that drives the cooling fan also had to be new, because the old one had a lot of wear. The scratched cylinder liner was replaced by a new cylinder liner, the segments were also new in the two pistons. The engine took the new gaskets and seals. The valves were rotated and clearance adjustment. The flywheel ring gear was also new because the old one was damaged.

Copyright © - All Rights Reserved - delfimpedrosa.pt